Sikaflex®-295 UV

Sikaflex®-295 UV is a 1-component polyurethane adhesive of paste-like consistency that cures on exposure to atmospheric moisture. It is suitable for interior and exterior sealing applications and to bond organic glass in the Marine business. Sikaflex®-295 UV meets the requirements set out by the International Maritime Organization (IMO).

- Excellent application properties

- Resistant to ageing and weathering

- Suitable for organic glasses

PRODUCT BENEFITS

- Excellent application properties

- Resistant to ageing and weathering

- Suitable for organic glasses

- Approved for the OEM market

- Wheelmark approved

Areas of Application

Sikaflex®-295 UV has been specially developed for the marine industry, where it is used to bond and seal plastic glazing materials in boats and ships. Because of its excellent weatherability this product can also be used to seal joints in exposed areas. Suitable substrates are aluminium (bright or anodized), GRP (polyester resin), stainless steel, timber, 2-component coatings and plastic glazing materials (PC, PMMA). Seek manufacturer’s advice and perform tests on original substrates before using Sikaflex®-295 UV on materials prone to stress cracking. This product is suitable for experienced professional users only. Test with actual substrates and conditions have to be performed to ensure adhesion and material compatibility.

| Chemical base | 1-component polyurethane

|

|

| Color (CQP001-1) | Black, white

|

|

| Cure mechanism | Moisture-curing | |

| Density (uncured) | 1.3 kg/l | |

| Non-sag properties | Good | |

| Application temperature | 10 ─ 35 °C

|

|

| Skin time (CQP019-1) | 60 minutes A | |

| Open time (CQP526-1) | 45 minutes A | |

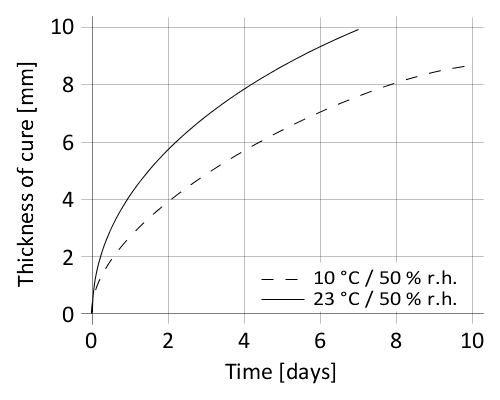

| Curing speed (CQP049-1) | (see diagram 1)

|

|

| Shrinkage (CQP014-1) | 1 %

|

|

| Shore A hardness (CQP023-1 / ISO 48-4) | 35 | |

| Tensile strength (CQP036-1 / ISO 527) | 2 MPa

|

|

| Elongation at break (CQP036-1 / ISO 527) | 500 % | |

| Tear propagation resistance (CQP045-1 / ISO 34) | 5 N/mm | |

| Service temperature (CQP509-1 / CQP513-1) |

|

-50 ─ 90 °C

|

| Shelf life (CQP016-1) |

|

12 months B

|

| CQP = Corporate Quality Procedure | A) 23 °C / 50 % r. h. | B) storage below 25 °C |

CURE MECHANISM

Sikaflex®-295 UV cures by reaction with atmospheric moisture. At low temperatures the water content of the air is generally lower and the curing reaction proceeds somewhat slower (see diagram 1).

Diagram 1: Curing speed Sikaflex®-295 UV

CHEMICAL RESISTANCE

Sikaflex®-295 UV is generally resistant to fresh water, seawater, diluted acids and diluted caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycolic alcohol, concentrated mineral acids and caustic solutions or solvents.

Application

Surface preparation

Surfaces must be clean, dry and free from grease, oil, dust and contaminants. Surface treatment depends on the specific nature of the substrates and is crucial for a long lasting bond. Suggestions for surface preparation may be found on the current edition of the appropriate Sika® Pre-treatment Chart. Consider that these suggestions are based on experience and have in any case to be verified by tests on original substrates.

Application

Sikaflex®-295 UV can be processed between 10 °C and 35 °C (climate and product) but changes in reactivity and application properties have to be considered. The optimum temperature for substrate and sealant is between 15 °C and 25 °C.

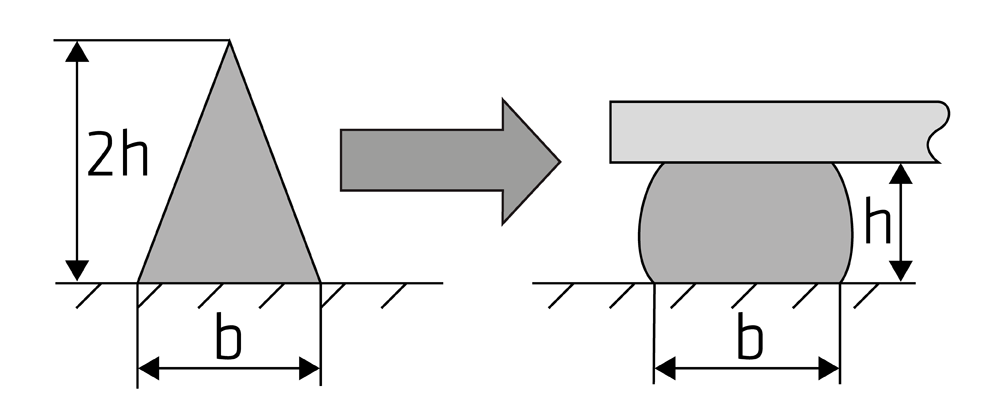

Consider that the viscosity will increase at low temperature. For easy application, condition the adhesive at ambient temperature prior to use. To ensure a uniform thickness of the bondline it is recommend to apply the adhesive in form of a triangular bead (see figure 1).

Figure 1: Recommended bead configuration

Sikaflex®-295 UV can be processed with manual, pneumatic or electric driven piston guns as well as pump equipment. The open time is significantly shorter in hot and humid climate. The parts must always be installed within the open time. Never join bonding parts if the adhesive has built a skin.

Tooling and finishing

Tooling and finishing must be carried out within the skin time of the product. It is recommended using Sika® Tooling Agent N. Other finishing agents must be tested for suitability and compatibility prior the use.

Removal

Uncured Sikaflex®-295 UV can be removed from tools and equipment with Sika® Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically. Hands and exposed skin have to be washed immediately using Sika® Cleaner-350H cleaning towels or a suitable industrial hand cleaner and water.

Do not use solvents on skin.

Overpainting

Sikaflex®-295 UV can be painted prior and after formation of a skin. If painting process takes place after the sealant has built a skin, adhesion could be improved by treating the joint surface with Sika® Aktivator-100 or Sika® Aktivator-205 prior to paint process. If the paint requires a baking process (> 80 °C), best performance is achieved by allowing the sealant to fully cure first. All paints have to be tested by carrying preliminary trials under manufacturing conditions.

The elasticity of paints is usually lower than that of sealants. This could lead to cracking of the paint in the joint area.

About Alpha Mare

Alpha Mare has been established in the year 2000 in Greece, in P.Faliro – an area close to the central port of Piraeus and also in the proximity of 6 marines in Attica, which places our headquarters in the very heart of the yachting life.

About Reflection

Reflection has been a trusted name in yacht and boat painting since its founding in 2001. With a long-term vision of expanding operations across the Mediterranean and Northern Europe, Reflection is the ideal partner for all yacht painting needs – ranging from standard maintenance to projects with high technical demands, including large yachts.